3 Common Furniture Finishing Material

When it comes to crafting beautiful and durable furniture, the finishing materials play a crucial role in defining both the aesthetics and longevity of the pieces. Whether working with solid wood, plywood, or MDF, the right finish can enhance the natural beauty of the material. Choosing the right finishing material for furniture depends on the desired aesthetic, the functional requirements of the piece, and the environment in which it will be used. These finishes serve multiple purposes, such as protecting the material from wear and tear, moisture, and UV damage, while also adding a desirable look and feel.

Today we will discuss 3 common furniture finishing material that are commonly used along with their benefits and applications which will help you make informed decisions for your next furniture project

1. Laminate

Laminate is a popular finishing material widely used in woodworking for its durability, versatility, and cost-effectiveness. It is made by pressing together layers of paper and plastic resins, with a decorative surface layer. Laminate is available in a vast array of colors, patterns, and textures. It can mimic natural materials like wood, stone, and metal, providing endless design possibilities.

From modern kitchens to sophisticated office spaces, laminate offers a practical and stylish solution for a wide range of applications.

With laminate, you can achieve specific looks and finishes that may be difficult or expensive to replicate with natural materials. For example, stone looking laminates are much cheaper and more durable option then the actual stone. Not only its lightweight but also its easy to install compared to a stone. You can see in the below photo how the laminate mimics like a stone.

Whether you want a marble finish look, cemented wall or metal finish look laminate is the most affordable option with various choices.

Look how the choice of a cement lookalike laminate changes the mood of the space and make it look completely rustic.

Laminate’s non-porous surface prevents moisture from penetrating, protecting the underlying material from warping and swelling. It resists stains from common household substances, maintaining its appearance with minimal effort. Hence, they can be used in outdoor areas as well. Below you can see that we have used the laminate in outdoor area of RaMa Home

The most important characteristic of laminate is that it can be applied to various substrates, including plywood, MDF, and particleboard, offering flexibility in furniture construction. Not only that as it is machine made so it provides a consistent look that is hard to achieve with natural materials, which can have variations in color and grain.

Below are some of the pros and cons of laminates

PROS

- Durable

- Resistant to scratches, stains, and impacts.

- Long-lasting even with heavy use.

- Cost effective

- More affordable than natural materials like solid wood or stone.

- Budget-friendly without compromising on quality or aesthetics.

- Comes in various designs

- Available in a wide range of colors, patterns, and textures.

- Can mimic the look of wood, marble, metal, and other natural materials.

- Ease of maintenance

- Non-porous surface is easy to clean.

- Resistant to spills and stains.

- Moisture resistant

- Suitable for use in kitchens and bathrooms due to resistance to moisture.

- Consistent

- Provides a uniform appearance across large surfaces and multiple pieces.

- Light weight

- Easier to handle and install compared to solid wood or stone.

- Reduces transportation and labor costs.

CONS

- Susceptibility to Chipping

- Can chip, especially at the edges, and is difficult to repair once damaged.

- Limited Repair Options

- Unlike natural wood, laminate cannot be sanded or refinished.

- Requires replacement if damaged.

- Heat Sensitivity

- Although resistant to moderate heat, can be damaged by excessive heat or direct exposure to hot objects.

- Synthetic Feel

- May lack the authentic look and feel of natural materials.

- Some people prefer the tactile and visual properties of real wood or stone.

- Installation Challenges

- Requires precise installation to prevent issues like bubbling or peeling.

- Edges and seams must be carefully finished to avoid moisture ingress and delamination.

Hence Laminate is a suitable finishing material for furniture because it combines durability, cost-effectiveness, aesthetic versatility, and ease of maintenance. Its ability to resist common forms of damage while offering a wide range of design options makes it an ideal choice for both residential and commercial furniture applications. This has always been a common finishing material and preferred choice for designers and architects and going to stay forever.

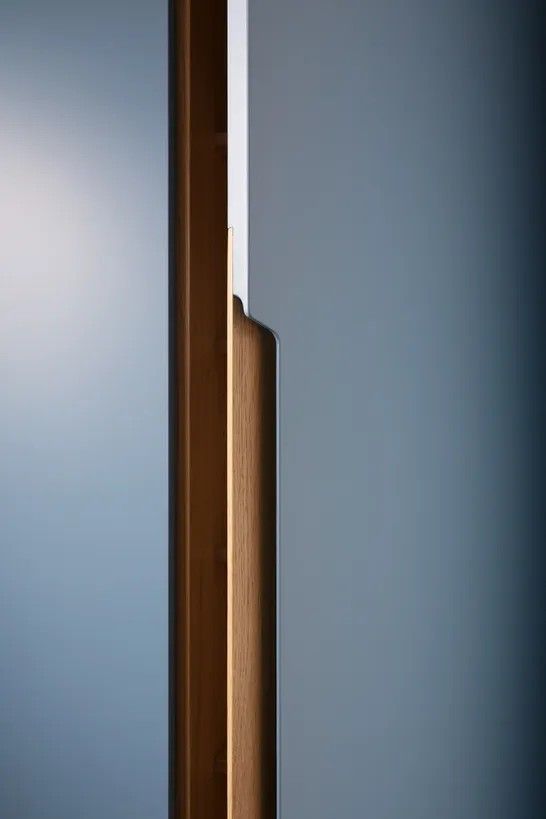

2. Veneer

Veneer is a thin slice of natural wood, typically less than 3 millimeters (1/8 inch) thick, that is glued onto core panels such as plywood, MDF (Medium Density Fiberboard), or particleboard.

Its manufacturing process involves the careful selection and preparation of logs, followed by slicing, drying, trimming, and assembly. The result is a versatile, cost-effective, and aesthetically pleasing material suitable for a wide range of applications in furniture, cabinetry, and interior design.

Laminate is valued for its strength, stability, and versatility in structural and non-structural applications however veneer is primarily preferred due to its aesthetic appeal.

Below are some pros and cons of veneer

PROS

Below are some pros and cons of veneer

PROS

- Aesthetic Appeal

- Veneer offers the rich, unique grain patterns of real wood, enhancing the visual appeal of furniture and interiors.

- Available in numerous wood species and finishes, allowing for a wide range of design possibilities.

- Cost-Effective

- Provides the look and feel of expensive solid wood at a fraction of the cost.

- Maximizes the use of valuable hardwoods, reducing waste and cost.

- Environmental Benefits

- Veneer production uses less wood, promoting sustainability and conservation of rare and exotic species.

- Stability and Durability

- Veneer, when applied to engineered substrates, is less prone to warping, cracking, and splitting compared to solid wood.

- The combination of veneer and its substrate provides a strong and durable surface suitable for everyday use.

- Versatility

- Suitable for furniture, cabinetry, wall panels, doors, and custom millwork.

Can be easily stained, painted, or finished to achieve the desired look and feel.

CONS

- Susceptibility to Damage

- Can be easily scratched, chipped, or damaged compared to solid wood.

- Damage can be difficult to repair; often requires replacement of the damaged veneer.

- Moisture Sensitivity

- Can delaminate if exposed to excessive moisture or humidity.

- Requires proper sealing and maintenance to prevent water damage.

- Complex Application

- Requires skilled craftsmen for proper application to avoid issues like bubbling, peeling, or uneven surfaces.

- Edges and seams must be carefully finished to prevent moisture ingress and delamination.

- Limited Refinishing

- Can only be sanded and refinished a limited number of times before the veneer layer is worn through.

- Excessive sanding or aggressive refinishing can damage the thin veneer layer.

Hence veneer is a versatile and cost-effective finishing material that provides the aesthetic appeal of natural wood. However, veneer requires careful handling, proper application, and maintenance to ensure its longevity and preserve its visual appeal. By understanding its pros and cons, you can make informed decisions when considering veneer for your furniture and interior design projects.

3. Paint

When it comes to finishing solid wood furniture, the choice of paint or polish can significantly influence its appearance, durability, and maintenance requirements. Each type of finish offers unique characteristics that cater to different aesthetic preferences and functional needs. There are various paint options such as Duco paint, Chalk paint, acrylic paint, PU paint, paint/polish for solid wood. Here, we delve into details of Duco paint as it is the most trending finishing material these days.

Duco paint is a premium finishing material celebrated for its high gloss and smooth texture. It’s a solvent-based paint that dries quickly to form a hard, durable coating on various surfaces, including wood, metal, and even certain plastics.

The key to achieving a flawless Duco finish lies in meticulous surface preparation. The surface must be clean, dry, and free of dust, grease, and any previous coatings. Sanding may be required to ensure a smooth base.

Duco paint is typically applied using a spray gun to achieve an even, consistent coating. This method allows for smooth application and minimizes brush marks or unevenness.

For smaller areas or touch-ups, Duco paint can be applied with a high-quality brush. Careful attention to brush strokes is essential to maintain a uniform finish.

The preferred base material to apply duco is MDF as it has smooth surface and lack natural imperfections such as knots that are common in solid wood. That doesn’t mean you have to make your furniture in MDF however the pro tip is applying thin MDF sheet on top of plywood and apply Duco paint on the same. You can see below the how we have applied Duco paint color in the crockery unit in RaMa Home.

Also fluted MDF are available which can be used for wall panel and any color can be applied to the same to match your design style and color palette. Below you can see how we have made this fluted wall panel on site using fluted MDF. The grey Duco color is applied on fluted MDF panel on site.

Whether used for modern furniture, architectural features, or decorative elements, Duco paint elevates the aesthetic appeal and durability of any project, making it a preferred option among designers and homeowners alike.

Tiles come in a variety of sizes, shapes, colors, patterns, and finishes, offering versatility in design and functionality for various applications in construction and interior design.

They are valued for their durability, ease of maintenance, and aesthetic appeal, making them a popular choice for both residential and commercial spaces. However, there are various types of tiles but below I feel are evergreen options and instantly adds a wow factor

Let’s see some of the pros and cons of Duco paint

PROS

- High Gloss Finish: Duco paint provides a luxurious, mirror-like gloss finish that enhances the aesthetic appeal of surfaces.

- Durability: It offers excellent resistance to scratches, moisture, and wear, making it suitable for both indoor and outdoor applications.

- Versatility: Available in a wide range of colors and shades, allowing for customization to match any interior or exterior design scheme.

- Smooth Application: Duco paint can be applied smoothly using a spray gun, resulting in a flawless finish without brush marks.

- Ease of Maintenance: The glossy surface of Duco paint is easy to clean and maintain with regular care.

- Quick Drying: Due to its solvent-based formulation, Duco paint dries relatively quickly, speeding up the overall painting process.

CONS:

- Application Complexity: Achieving a professional finish with Duco paint requires skill and experience, particularly in spray application techniques.

- Ventilation Requirements: Due to its solvent-based nature, Duco paint application requires adequate ventilation to prevent inhalation of fumes and ensure safety.

- Environmental Impact: Solvent-based paints like Duco may contain volatile organic compounds (VOCs), which can contribute to air pollution and require proper disposal practices.

- Cost: Duco paint tends to be more expensive than water-based paints due to its high-quality materials and application expertise required.

- Yellowing: Over time, certain formulations of Duco paint may yellow, especially in areas exposed to sunlight or UV radiation.

- Surface Preparation: Proper surface preparation, including priming and sanding, is crucial to achieve optimal adhesion and finish quality with Duco paint.

Understanding these pros and cons can help you determine whether Duco paint is the right choice for your painting project, taking into account factors such as budget, environmental considerations, and desired finish quality.

This brings us to the end of the blog. I hope you find this helpful and make informed decision in your future projects.

In conclusion, laminate, veneer, and duco paint each offer unique advantages as finishing materials for woodwork. Laminate is known for its durability, ease of maintenance, and a wide variety of design options, making it ideal for high-traffic areas. Veneer, on the other hand, provides the elegance and natural beauty of real wood at a more affordable cost, offering a rich and luxurious finish. Duco paint delivers a smooth, glossy, and vibrant finish that enhances the aesthetic appeal of furniture and cabinetry, while also providing a durable and easy-to-clean surface. By selecting the appropriate material based on specific needs and preferences, one can achieve a perfect balance of functionality and style in their woodwork projects.

Remember to here to keep getting updates

Until Then Take care and Keep learning!!

See you soon…

Megha Srivastava